Aerospace

- Home

- Aerospace

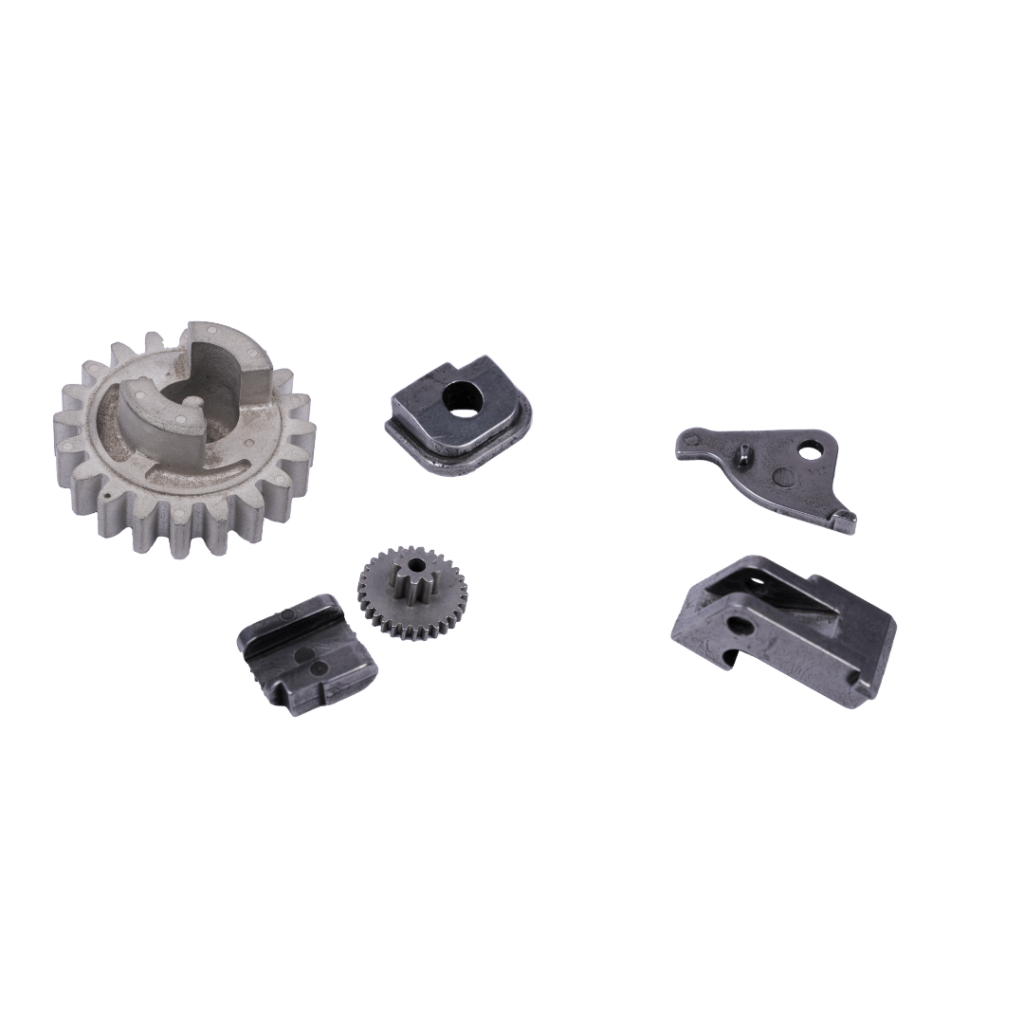

MIM Parts For Aerospace Solutions

Meta Build supplies MIM parts for the aerospace sector, boasting the combined capabilities of a precision machine shop and a special process plant within a top-tier, cutting-edge facility.

We offer quality and efficiency to the demanding clientele of the Aerospace industry. Our meticulously crafted products reach global OEMs punctually, without fail.

Our skilled engineers excel at producing complex machined components, utilizing premier machine tools and processes. We have the capability to manufacture, treat, plate, paint, and test parts entirely in-house, ensuring seamless production and quality control.

As a leading supplier of Metal Injection Molding (MIM) parts, we are dedicated to serving the aerospace industry with components that set the standard for excellence and reliability. Our commitment to quality and precision underpins every part we deliver, ensuring that our aerospace clients receive only the best in class solutions.

Our Aerospace Offerings

At Meta Build, we understand the critical demands of aerospace engineering — a field where every component must perform flawlessly under extreme conditions. Our MIM parts are engineered to meet these challenges head-on, offering unparalleled precision, strength, and durability.

State-of-the-Art Manufacturing

Our world-class facility is equipped with cutting-edge technology and a precision machine shop, allowing us to produce MIM parts that are at the forefront of aerospace technology. We blend traditional craftsmanship with modern manufacturing techniques to create parts that exceed industry standards.

Comprehensive Capabilities: From machining to plating, painting, and testing, all processes are conducted in-house for maximum quality control.

Experienced Engineering Team: Our engineers bring their extensive expertise to every project, ensuring that each component is manufactured to the highest precision.

Timely Delivery: We pride ourselves on our ability to deliver high-quality products on time, every time, to aerospace OEMs around the globe.

Why Choose Meta Build for Aerospace MIM Parts?

Precision and Reliability: Our MIM parts are synonymous with precision and reliability, essential for the aerospace industry.

Customization and Flexibility: We offer customized solutions to meet the unique challenges of your aerospace projects.

Quality Assurance: With our comprehensive in-house capabilities, every part undergoes rigorous testing and quality assurance processes.

Global Reach: We supply to aerospace OEMs worldwide, ensuring that our top-quality parts support the global aerospace industry.

At Meta Build, we are not just suppliers; we are partners in your aerospace endeavors. Our commitment to innovation, quality, and efficiency makes us the preferred choice for MIM parts in the aerospace sector. Let us help you soar to new heights with components that truly make a difference.

Processing Capabilities

- Fluorescent Particle Inspection

- Magnetic Particle Inspection

- Conductivity Testing

- Hardness Testing

- Grain Flow Check

- Acid Etch Inspection

- Anodic Flaw Detection

- Primer Application

- Semi-Gloss and High-Gloss Paint Application

- Abrasion Resistant Paint Application

- Over Coat Application

- Masking Solutions

- Solid Film Lubricant

- Electrochemical Etch Marking

- Ink Jet Part Marking

- Chromic Acid Anodizing/ Sulfuric Acid Anodizing

- Boric Acid/ Sulfuric Acid Anodizing

- Sulfuric Acid Anodizing

- Electroless Nickel Plating + w/ Teflon Coating

- Chemical Conversion Coating

- Cadmium Plating/ Nickel Cadmium Plating

- Zinc Plating w/ Blue and Yellow Passivation

- Manganese Phosphate w/ Solid Film Lubricant Coating

- De-Ionized Water, Nickel Acetate, Dichromate, Dye and Clear Sealing Process

- Aluminum Etching

- Hard Anodizing

- Chrome Plating

- Zinc Nickel plating

- Hard Anodizing with Teflon Impregmentation

- Salt Spray Chamber

- Ph, Conductivity, TDS Meter

- Metal Conductivity Meter

- Cross Hatch Tester

- UV-Visible Spectrophoto Meter

- Distillation Unit

- Quantitative and Qualitative Chemical Analysis

- Coating Thickness-DT/NDT-Eddy Current

- Coating Weight Test

- Magnification Lens

- Muffle Furnace

- Chemical Balance

- Gloss Meter

- Millipore Testing

- X-Ray Testing

- Aluminum Oxide Cleaning

- Ultrasonic Cleaning

- Vapor Degreasing

- Vacuum heat treatment

- Solutionizing

- Age Hardening

- Atmospheric Heat Treatment

- Normalizing

- Stress Relieving