MIM Application

- Home

- MIM Application

Metal Injection Molding (MIM) Applications

Various industries need parts of different sizes and precise specifications for their machinery. The use of metal injection molding (MIM) has revolutionized the production of smaller components. Some of the key sectors that have widely adopted MIM parts include the automotive, medical, aerospace, and consumer goods industries.

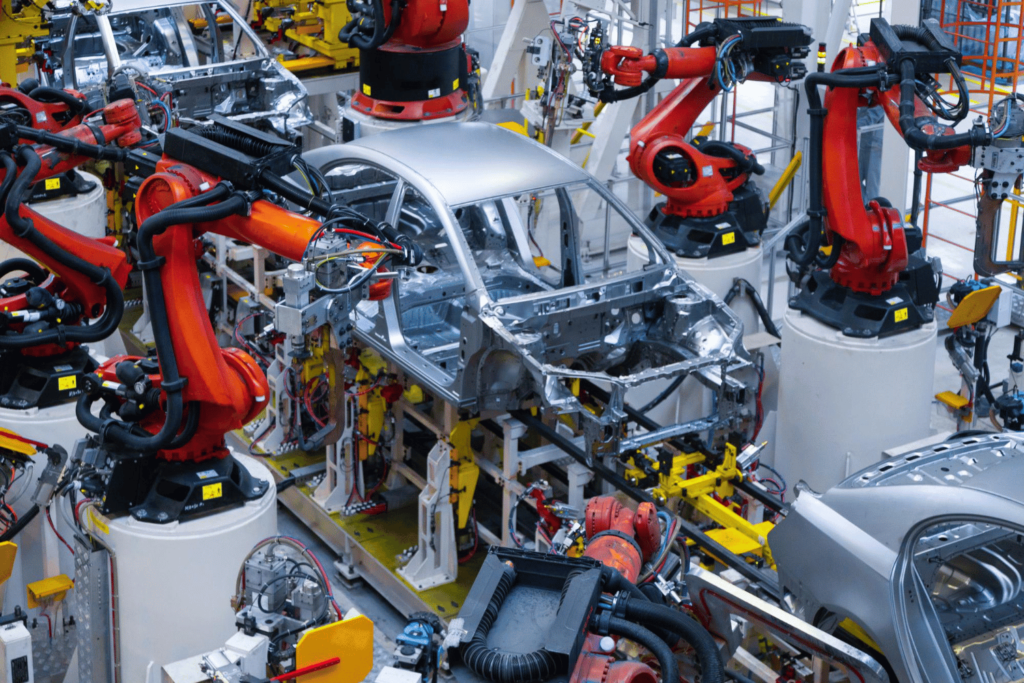

Automotive Industry

The automotive sector heavily relies on MIM parts for its need for small, dimensionally accurate components across different systems. These parts find applications in engines, transmissions, fuel injections, and steering mechanisms.

The industry benefits from using MIM for creating gears, brackets, connectors, pulleys, and various other compact, precisely engineered components that demand high precision and robustness.

MIM parts are particularly valued in automotive manufacturing due to their resistance to high temperatures, corrosion, and their overall strength, making them perfectly suited for the demanding environment of the automotive industry.

Aerospace Industry

The aerospace sector demands parts that combine high performance with light weight and durability. MIM components fulfill these requirements, making them a popular choice for manufacturing small, intricate, and precisely shaped items such as fuel injectors, valves, actuators, and electronic connectors.

Preferred in the aerospace industry for their superior strength-to-weight ratio, ability to withstand high temperatures, and outstanding corrosion resistance, MIM parts are essential in environments where they are subjected to dense packing and high-pressure conditions.

Medical Industry

The medical sector demands parts of the highest quality and precision that must also be biocompatible and capable of sterilization. In this field, MIM parts are used to produce exact components like surgical instruments, orthodontic braces, dental implants, and medication delivery systems.

Their widespread use in healthcare stems from their compatibility with biological tissues, precise manufacturing standards, and the ability to be effectively sterilized.

Consumer Goods Industry

Consumer goods industry requires parts that are not only durable and aesthetically appealing but also cost-effective and of high quality.

MIM components are utilized in this industry for creating detailed, complex, and small items such as locks, buttons, hinges, as well as decorative or functional elements. The preference for MIM parts in the consumer goods sector is attributed to their precision, exceptional surface finish, and affordability.